product impact testing|benefits of impact testing : purchaser Impact tests are short-term tests which provide information on the failure behavior of materials or components subjected to rapid loading and at varying temperatures. The testing systems used . Resultado da For Gracie family fighters , the 100 most-recently updated member lists will be included. close. input. Pick 'Em & Fantasy Games - All the biggest upcoming MMA & Boxing fights - Create a free Tapology account to play. Event . UFC Fight Night 238: How to watch Jairzinho Rozenstruik vs. Shamil Gaziev, .

{plog:ftitle_list}

27 de dez. de 2023 · Onde assistir ao Jogo das Estrelas de Zico. TV: SporTV; Ficha técnica do Jogo das Estrelas de Zico. Data: 27/12/2023; Horário: 20h30 (horário de .

Impact tests are short-term tests which provide information on the failure behavior of materials or components subjected to rapid loading and at varying temperatures. The testing systems used .

Impact testing equipment plays a vital role in the design and development of products. Manufacturers use impact testing to choose the most reliable materials for their products. It can help ensure that they meet the necessary .

why impact testing is done

what is impact testing

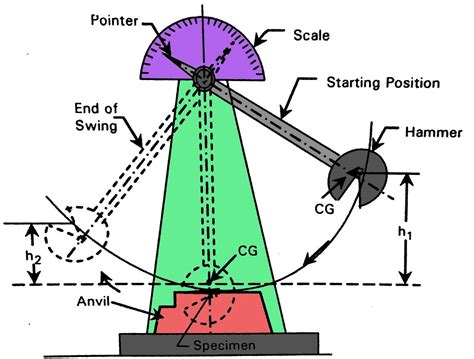

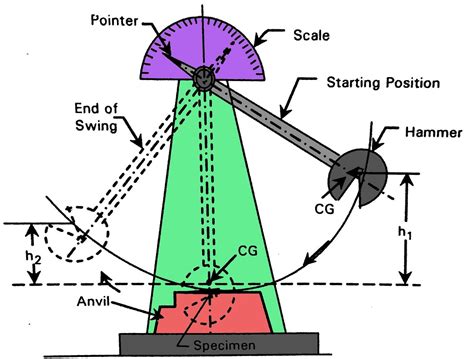

Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch . Specimen Position. Horizontally, Notch facing away from the pendulum. Vertically, Notch .At ImPACT Applications, Inc. our mission is to help reduce the risks associated with concussion. We do this by supporting people who care for and manage athletes and patients around the world. Our products, ImPACT, ImPACT .Impact Testing It is the measure of a material’s resistance to the sudden application of force. Measuring properties like plastic deformation, ductility, and brittleness of materials is essential for proper material selection, ensuring quality control and reliability for finished products. Depending on the sample requirements, experts choose . Analyze user behavior, conversion rates, and performance indicators to gauge the impact of testing on your product’s success. This data-driven approach to project monitoring helps in making informed decisions. Remember, the product testing process is a continuous journey. Plan for regular testing and updates post-launch to ensure your product .

Let's look at the impact test machine (or Charpy impact tester) commonly used for assessing the impact resistance of products and materials.You'll learn:☑ Wh.Impact testing plays a crucial role in material science, engineering and product development by providing insights into a material’s response to sudden loads. By measuring a material’s resistance to impact and facture behaviour, our tests can support you in designing safer, more reliable products. Tips for product testing Here are some tips to help your team conduct product testing during the development process: Use different methods: It's helpful to use different product testing methods to provide clear direction throughout all phases of development. For example, your team may use concept testing to determine the viability of a product idea, A/B .Product drop testing and package drop testing provide insight into their design by evaluating how well items withstand tumbles, drops, and other types of impact throughout their lifecycle. Armed with this information, manufacturers can address design flaws and different build options to improve durability in order to minimize product damage .

Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models. The new 9400 Series produces reliable, repeatable results whether you are testing materials and components before production to improve product acceptance or testing during production to ensure continuous improvement.Drop Weight Impact Testing Machine. Impact Tester for Plastics, Composite, Light Alloys and Components . Electronics and Consumer Products over a wide range of materials. Handle the Most Demanding Analysis The 9450 drop weight impact testing machine capabilities can be expanded to include 24 m/s impact velocity, extra wide test chambers and . Over the course of your product lifecycle as a Product Manager I recommend moving from level 1 through to level 4, doing whatever it takes to get there. Level 1: anecdotes Level 2: usage and .

Impact testing is testing an object's ability to resist high-rate loading. An impact test is a test for determining the energy absorbed in fracturing a test piece at high velocity. . More importantly these days, it involves the perplexing problem of product safety and liability. One must determine: The impact energies the part can be expected .Dynamic, Fatigue, Impact, and endurance, reliability testing systems for evaluation of materials, parts, and finished products North America. Analytical and Measuring Instruments. About Shimadzu . Fatigue Testing/Impact Testing Products . Showing 1 - 10 of . 11. Hide Discontinued Series . EHF-E Series.Impact testing is a type of mechanical testing used to determine how a material responds to high strain-rate loading. It involves instrumented equipment measuring loads and energy absorbed by the material when it fractur es. The .

Impact testing is a critical step in ensuring the safety of plastic products. This article explains the importance of impact testing and how to perform it. . In the end, the choice of impact testing type depends on the goal. Product design, material characterisation, quality control, inspecting incoming material, and R&D are a few of the .An IP tear or impact test simulates the real world challenges that your products will face. Take a look at some of the impact testing, impact strength test and falling weight impact testing that we can support. Advanced pendulum impact testing system. The Ray-Ran advanced pendulum impact testing system is a pendulum impact tester.Impact testing is testing an object's ability to resist high-rate loading. An impact test is a test for determining the energy absorbed in fracturing a test piece at high velocity. . More importantly these days, it involves the perplexing problem of product safety and liability. One must determine: The impact energies the part can be expected . “The impact fracture properties of materials are also used in the selection of product materials and in fundamental data for quality control, being greatly applied for the purpose of improving R&D efficiency and product reliability.” Impact testing is also important for plastics used in applications that are not safety critical, such as .

metal impact testing equipment

Drop weight impact test calculations measure the toughness of polymers and composites used in many automotive and aerospace applications. Ensuring that these calculations are as accurate as possible is critical. . This way, OEMs can prevent downtime and product recalls further down the supply chain. Choosing your Drop Weight Impact Testing .For windows and doors, the impact test consists of firing a 2x4 projectile at predetermined locations. The cycling portion of the test is conducted after the impact test with no penetrations and consists of 9,000 cycles of positive and negative pressures. . Air, Water, and Structural testing; Florida Product Approval requirements; Miami-Dade .Impact testing has become firmly established in materials and components testing. The properties determined are part of basic material characterization. ZwickRoell has been delivering quality impact test equipment for years. Our product line includes pendulum impact testers for metals and pendulum impact testers for plastics, .ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our milestones here and access our press releases here.

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . Understanding impact can drastically change the priorities of any product team. And while assessing impact is extremely important, it is also extremely difficult to actually do. The pitfalls of existing impact analyses. Until now, product teams had two options to assess the effect of their product launches on their key metrics.

Fatigue and impact testing is used to determine the durability (fatigue strength and impact properties) of raw materials or components under various environmental conditions. It is widely used for industries such as automotive, aerospace, medical, apparel, construction, etc. . Our product lineup includes the EHF-E series flagship model, which .

ImPACT is a computerized concussion assessment tool for ages 12-59. By comparing baseline and post-injury ImPACT test results, you can make confident treatment decisions.

impact testing materials

impact testing equipment

how does an impact test work

examples of impact testing

No Prêmio IYálodè, Marcelo Fritz contou rapidamente como conheceu Babá Mauro e como surgiu a ideia do Prêmio Iyalodè e da importância de valorizar os...

product impact testing|benefits of impact testing